Basement Waterproofing and Combined Protection

'Combined Protection' is a section within BS8102 Code of practice for protection of below ground structures against water ingress; it advises that designers consider the use of two forms of waterproofing, either where there are aggressive site conditions (it's a wet one), or the consequences of failure are high (few pennies required if it goes wrong).

This approach has been widely adopted in residential (specifically habitable space) new-build because the consequences of issue historically have been particularly costly. The best data that we have on this is that which was published by the NHBC in 2014, in relation to their claims spend which was £20.5 million pounds over an eight year period (£13k per day).

It's completely understandable why 'combined protection' / dual forms of waterproofing has been widely adopted in residential, but there are three forms of waterproofing to choose from, so what to select and specifically why do we and others always include cavity drainage?

Firstly, to cover the basics, these 'types' are defined within BS8102 as:

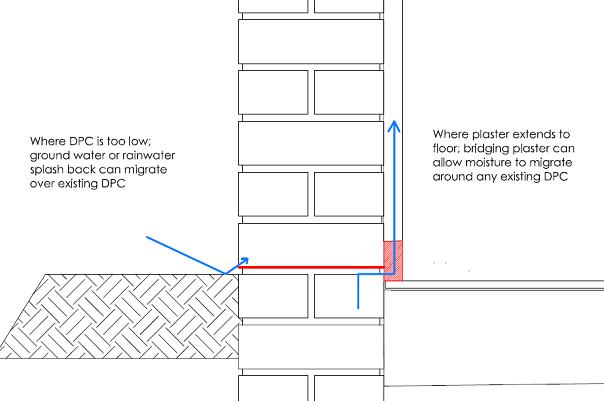

Type A, which is 'barrier tanking', this is where a specific barrier material is installed on or within the structure, to block water out.

Type B, is 'structurally integral protection', essentially where the structure itself is the barrier to block water out - typically reinforced concrete but can also include steel sheet piling.

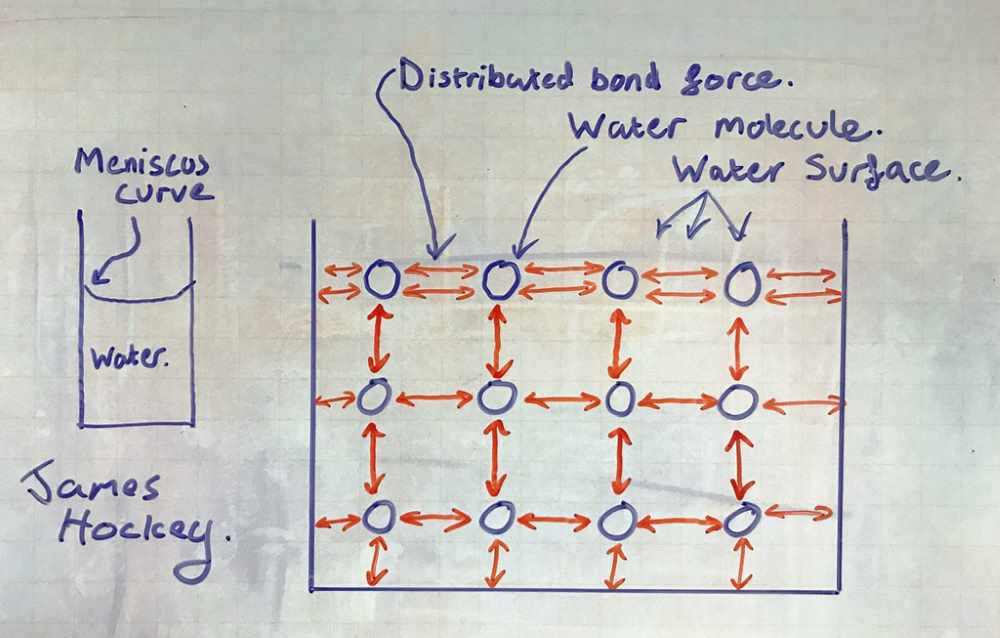

Type C, is 'drained protection' - commonly referred to as 'cavity drainage'. Any water ingress is collected, removed, and isolated from the interior with vapour barrier membranes.

Tanking and integrally waterproof structures, both take the approach of seeking to block water out. Cavity drainage is fundamentally different in the way in which it protects, by relying on means of drainage.

To draw an effective conclusion on picking two of the three, we need to consider the implications of different combinations, including what happens in the worst case, i.e. the consequences of failure.

My position on this is based upon my experience. I dealt with my first structural warranty/insurance claim on a failed basement waterproofing system in 2006, and am still dealing with them now. You only have to look at the level of NHBC spend stated above to understand the extent of issues and resulting requirement for this work, and I think we've probably done more of it than any other in the UK. As an aside we also helped Premier Guarantees re-write their technical guidance in 2011/12 to manage risk, which started the ball rolling and others followed, some of whom we've also assisted.

In any case, almost all of the claims we've dealt with were on systems that seek to block water out, I think in part because historically this was just the de facto approach. Note that proportionately the total number of waterproofing systems that fail is 'relatively' low, i.e. 2.5% failure rate according to NHBC statistics, so it's not the case that every one of these systems falls over, it's just that when they do, it can be substantially costly and simply - this is what must absolutely be avoided.

Understanding the root cause of that cost implication, assists in understanding which systems to select.

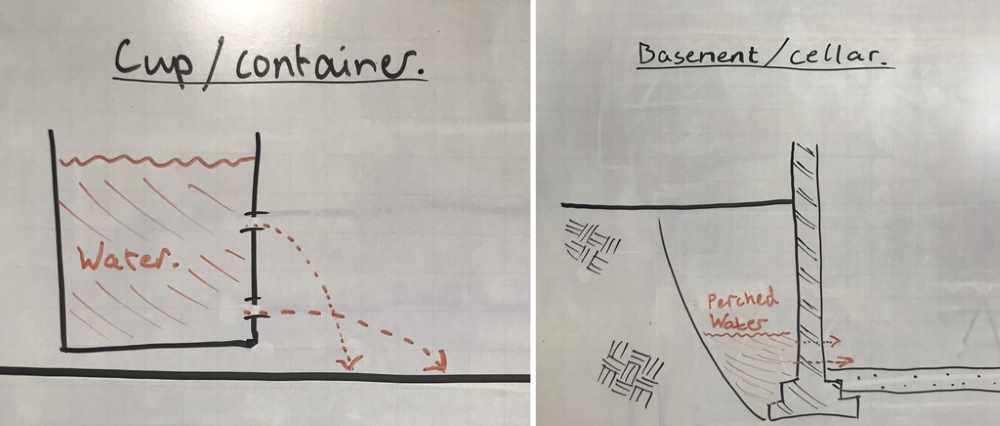

At the time of writing I'm involved with an externally tanked eco-mansion type property suffering issues of water in the floor construction at basement/lower ground level, where rooms include bar/games room, cinema, gym, and swimming pool.

It's a very high standard of fit out, but any extent of internal fit out has implication when assessing finished basements for issues of water ingress. This is because, you cannot readily see the structure (which remember can itself be the waterproofing), or any waterproofing barriers applied on or within it.

In that case the internal wall and floor build up is typical - insulated plasterboard to retaining walls, with a build up of insulation/polythene/screed/floor finishes over the raft. Internal walls are dot & dab fixed boards.

It is entirely possible, if not common, that with such a build-up, the position at which you see water damage to finishes internally, is not the same position in which the water actually penetrated.

Water can ingress at one location, travel unseen over the raft within the depth of the floor insulation, then showing up somewhere else. For example, I've stood in basements where the internal walls are suffering issue, but all the externals are pristine.

How can you then categorically know what and where the point of ingress is?

You can look into a wall/floor construction in one area, which might be 0.001% of the total area of retaining structure, and see water/dampness but not be able to see where this has come from, and it's complicated further by any issues of leaking services (should always form part of any investigation), pool issues, drains etc. etc.

This was a typical position in which the insurers found themselves and the options would be to try and implement localised works or rule out certain factors, or bite the bullet and deal with the claim comprehensively to ensure a right first time solution.

What this actually means is fully stripping out a property at basement level and installing internal cavity drainage to all walls and floors.

The extent of this work results in the level of spend indicated, however with the use of cavity drainage, a number of key benefits were and are provided:

- Fundamentally, the method assumes and still works if ingress occurs, so is ideal in a remedial setting.

- Get the drainage aspect right, and water pressure never comes to bear on the membranes. BS8102 states that designers must assume risk of defects (in any system). If water pressure never bears upon an assumed defect within a cavity membrane, it will not move through that defect and so the system inherently takes account of defects as per BS8102. Also assists in achieving a right first time solution.

- Cavity drainage can be water tested during construction to prove function. Also assists in achieving a right first time solution.

This isn't the be-all end-all list, but in the context of the question regarding system selection, I would ask a further question:

If this is so effective in designing out issues in a remedial setting, why wouldn't it be just as good when employed as part of a dual/combined system in a new-build scenario?

Well, it is, and this is why we and many others like us providing long term guarantees, use it as part of a combined system (with the other element being either form of 'barrier'), to avoid situations where our own insurers might have to spend significantly to put right issues of ingress.

I do think and accept that from an end user perspective, the absolute ideal would be for no ingress to occur, and there is greater chance of achieving this when using a combination of barrier systems (tanking + structurally integral protection), however this combination can still suffer issue and then have the cost implications as described, and in my view it's just not worth it when there are ways in which such implications can be better designed for.

Additional comments and conclusions:

Tanking and structurally integral protection both function by providing a barrier to block water out. A combination of such systems seeks to achieve the same outcome via the same method.

The barriers or combination of them must be perfect (free of defects) in order to exclude water where pressure comes to bear (must assume that pressure bears to comply with BS8102, and that defects can occur in any given system).

Dependent on configuration one system can protect against defects in the other (a benefit) but is influenced by configuration, and while combined barriers provide enhanced/lower risk levels, nothing is completely without risk.

In a residential setting, the implication of issues can be significant.

The only way to truly test a barrier based system, is to subject it to hydrostatic pressure, i.e. the ground around the structure is fully saturated. Unless high water table is already present and proven, this isn't something that can be 'manufactured' on site, and the point at which pressure bears can be well after completion and occupation.

The combination of a barrier (tanking OR structurally integral protection), with cavity drainage system, employs two fundamentally different methods, and the advantages of cavity drainage overcome the disadvantages in barrier methods, providing an overall lower risk level.

Risk on any scheme will always be influenced by a combination of design, installation and materials selection, but in my view design is the first and most important aspect, and that is exactly what we are talking about here.

Ultimately the acceptable failure rate should be zero. Best way to achieve this is with a barrier and cavity drainage system.

Proponents of combined barrier systems (no cavity drainage), typically are not providing the same level of guarantee cover as the designer/installer contractors that prefer to include cavity drainage.

Everyone is entitled to an opinion, mine is that if any individual/company is providing the level of guarantee cover that we are, they will most likely share our view.

Footnote: Remember, the above is specific to a finished/habitable space! This is an article primarily intended to inform the public of our position, not to raise debate within the waterproofing industry (although it may), even if this is part of the outcome.

James Hockey

.JPG)

.JPG)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)